Oil and Gas Turbine Repair

At AERO Component Repair, LLC™, we have the capabilities, processes, experience, and machines to meet the gas turbine repair needs of the oil and gas industry. The industrial gas turbine are used in the oil and gas industry to drive pumps that pull natural gas or oil from deep within the earth.

Gas turbine are also used to generate electricity on oil platforms. When a gas turbine needs the blades re-tipped, airfoil for the turbine nozzle, or dimensional restoration, we are the best choice to carry out these gas turbine repair.

We can also do Saturn™ hub replacement in-house and Centaur™ air/oil seal or ID coating restoration. If you need a new tilt pad bearing, we can supply it for your Centaur™ engine. Regardless of the gas turbine repair you need, we do great work and pride ourselves in providing excellent customer service.

Solving Problems

With the exception of short shutdowns for maintenance, gas turbines used in the oil and gas industry operate continuously. These gas turbines run between five and eight years nonstop. This illustrates how important part longevity is to this industry and why we have to ensure every repair is technically correct and keep the long-term operation in mind.

In addition to working directly with oil and gas customers, we work with field service companies. Field service companies bring us the gas turbine parts they can’t repair in the field for a precise repair and a fast turnaround.

Applications

We solve a number of unique turbine problems faced by the oil and gas industry. The following are gas turbine components and what we can do to repair them:

Turbine nozzles

- Airfoil contour restoration, crack repair, pit repair, and FOD of the part

- Machine gas path diameters to concentricity and size

- Replace center hub, fluoride ion clean, braze, and airfoil insert installation

- Restore airfoil/gas path protective coatings

Inner and outer combustion liners

- Repair cracks and defects through welding

- Reverse fretting wear by restoring thickness

- Restore dilution hole geometry, thickness, and diameter

- Restore baffle geometry and cooling hole

- Fit with mating parts by restoring part contour

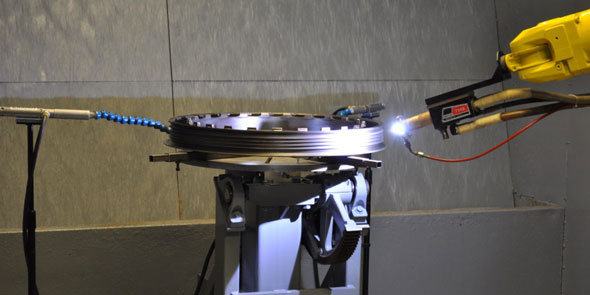

Gas Turbine shaft air/oil seals

- Dimensional and visual inspection

- Remove worn bearing material through pre-machining

- Restore bearing material through flame spraying

- Machine to final size post-assembly and restore holes and oil groove

- Final inspection and cleaning

Gas Turbine blades

- Fluorescent penetrant inspection (FPI)

- Damaged material removal

- Restoration of geometry and tip length through welding

- Restore contour and geometry through hand finishing

- Restore protective coating

- Cleaning and polishing

Turbine nozzle segments

- Airfoil contour restoration, crack repair, pit repair, and FOD

- Replace or restore stage 1 cooling grommets

- Heat treat

- Restore blade path flame sprayed coatings

- Brazing, fluoride ion cleaning, and airfoil insert installation

- Airfoil/gas path protective coating restoration

Our welders are certified to AWS D17.1, and our NDT inspectors are certified to ASNT Level II FPI/MPI.